Editor’s summary

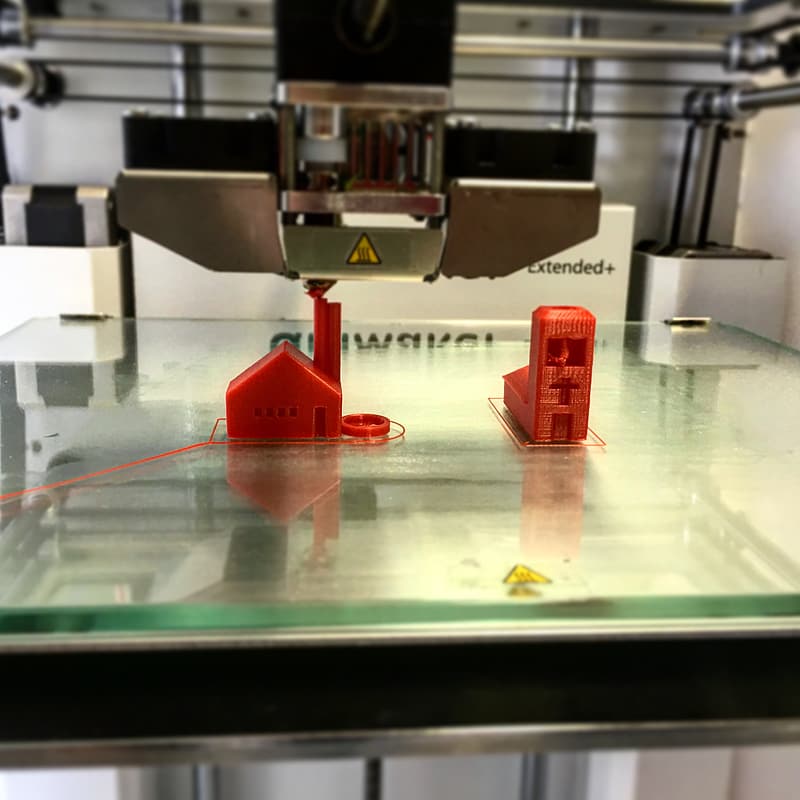

Most methods for three-dimensional (3D) printing of polymers use focused light to control the formation of volume units (voxels). Kuang et al. developed a technique that they call deep-penetrating acoustic volumetric printing (DAVP), which uses a viscoelastic ink and high-intensity focused ultrasound (see the Perspective by Yao and Shapiro). A key feature of the technique is the sono-ink they used, which prevents curing beyond the focal point, thus preventing solidification beyond the intended voxel. A key advantage of using ultrasound is that it can penetrate multiple centimeters deep into opaque media. —Marc S. Lavine

Abstract

Volumetric printing, an emerging additive manufacturing technique, builds objects with enhanced printing speed and surface quality by forgoing the stepwise ink-renewal step. Existing volumetric printing techniques almost exclusively rely on light energy to trigger photopolymerization in transparent inks, limiting material choices and build sizes. We report a self-enhancing sonicated ink (or sono-ink) design and corresponding focused-ultrasound writing technique for deep-penetration acoustic volumetric printing (DAVP). We used experiments and acoustic modeling to study the frequency and scanning rate–dependent acoustic printing behaviors. DAVP achieves the key features of low acoustic streaming, rapid sonothermal polymerization, and large printing depth, enabling the printing of volumetric hydrogels and nanocomposites with various shapes regardless of their optical properties. DAVP also allows printing at centimeter depths through biological tissues, paving the way toward minimally invasive medicine.